Engineers improve powertrains pursuing better fuel efficiency and more power, combining the latest technology with existing principles of fuel consumption. The fundamental differences between engines lie in fuel consumption type and in how they generate power, so understanding the basics can help you choose the right powertrain according to your needs. In this article, we’re reviewing how direct injection works.

What is direct injection

Direct injection is a combustion technology that improves the availability of torque and power by burning the air-fuel mixture more efficiently. Direct injection itself isn’t a groundbreaker. It was introduced in the 1950s on the German sports car with the revolutionary gullwing doors, the Mercedes-Benz 300 SL. Mass-produced cars with direct fuel injection (GDI) entered the market in the 1980s when noisy carburetors were deemed inefficient.

How does direct injection work

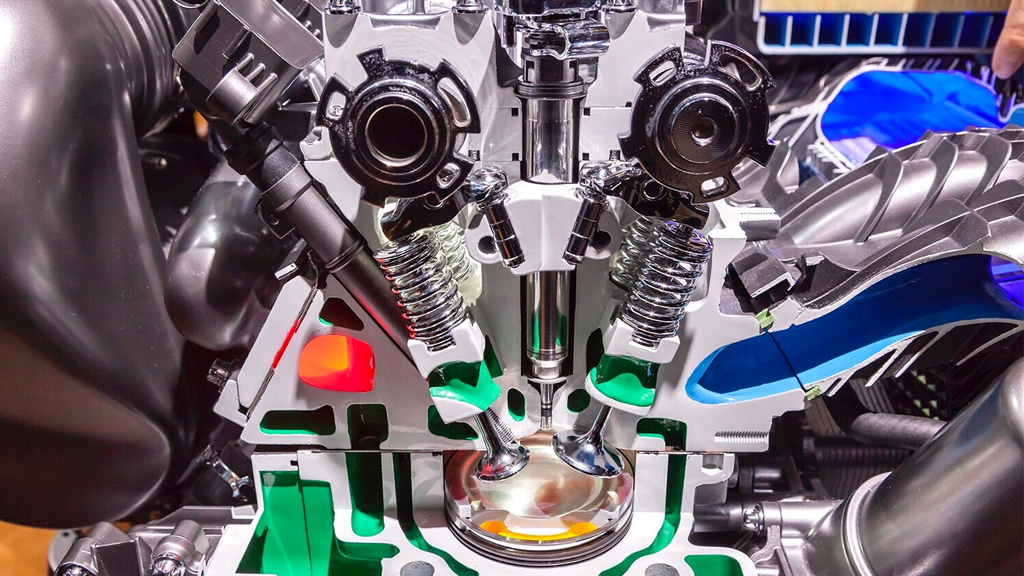

The main difference between direct fuel injection and a standard gasoline engine is the fuel delivery, leading to power production inside the combustion chamber. A gasoline engine gets its power through an air-fuel mixture delivered directly into the cylinder, compressed with a piston. Then, the mixture explodes with the help of spark plugs, and high compression forces the cylinder downwards. As a result, the mixture injected into the cylinder doesn’t burn efficiently because of unbalanced delivery, losing available power due to inaccurate fuel dispersal.

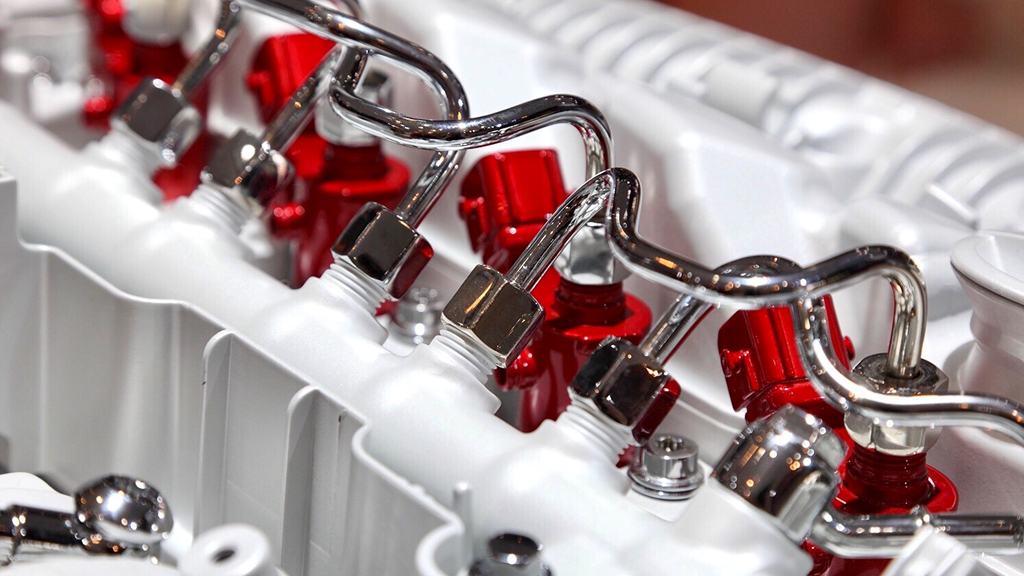

Direct fuel injection doesn’t require mixing the air with fuel. The air is injected into cylinders via an air intake manifold, while the gasoline comes from a single injector placed aside or under the cylinder. Electronically controlled fuel injection contributes to lower emissions and noise, and higher compression ratios provide more instant power by injecting smaller droplets of fuel that cover the entirety of the cylinder. GDI engines are similar to diesel, where ignition occurs due to heavy compression.

Pros and cons of direct injection

Direct injection offers better overall efficiency, including reduced fuel consumption, lower carbon oxide emissions, and more potent fuel delivery. But it also has some drawbacks: for instance, carbon falls onto valves and bakes there. GDI construction doesn’t allow cleaning the valves as you can do in a car with a standard gasoline engine. If you notice that valves are covered in a black substance, you’ll have to contact a qualified technician to arrange a diagnostic and a complete replacement.

The increased pressure can affect fuel pumps since they need to work faster. The complicated construction of gasoline direct injection engines makes them more expensive to maintain and repair.

Bottom Line

Direct injection engines are getting more complex, have better fuel economy and low emissions. Cars with direct injection are rising in popularity since fuel-efficiency and ecology are major concerns for both customers and automakers. If you’re looking for a car with direct injection on a budget, get started with Salvagebid. You can find a lot of great deals on clean and salvage title cars on our online auto auction. Register with us, provide a copy of your passport or government-issued ID, and place a refundable security deposit to start bidding right away from the comfort of your home. Don’t hesitate to contact us online or give us a call at + 1 (360) 347-1300 (6:00 AM – 3:00 PM PST, Monday to Friday) if you have any questions.